Due to the failure of the coupling itself, it needs to be disassembled. First, the entire coupling must be carefully and carefully inspected (especially for the damaged coupling), and the cause of the failure should be found out. Brass carbon steel pipe nipple supplier shares with you.

Before disassembling the coupling, make some marks on the positions of the coupling parts and components for mutual reference. For couplings used in high-speed machines, the coupling bolts have been weighed, and the marking must be clear and must not be mistaken.

When disassembling the coupling, the coupling bolts are generally removed first. Because a layer of grease, corrosion products, and other deposits are deposited on the surface of the thread, it is not easy to disassemble the bolt, especially for bolts with severe corrosion, disassembly is very difficult. A suitable tool must be selected for the removal of the coupling bolt because the bearing surface of the bolt's outer hexagon or inner hexagon has been slipped and damaged, and the removal will be more difficult. For bolts that have been rusted or have a lot of greasy dirt, often the solvent (such as a rust-releasing agent) is used to spray the joint between the bolt and the nut to allow the solvent to penetrate into the thread so that it can be easily disassembled. If the bolt cannot be removed, the heating method can be used, and the heating temperature is generally controlled below 200 ° C. The gap between the nut and the bolt is enlarged by heating, and the rust is also easily dropped, making it easier to remove the bolt. If none of the above methods work, the only problem is to destroy the bolt, cut or drill off the bolt, and replace it with a new bolt during assembly. The new bolts must be the same as the original bolts. The new bolts used for high-speed equipment couplings must also be weighed so that the new bolts have the same weight as the connecting bolts on the same set of flanges.

During the coupling disassembly process, the most difficult task is to remove the hub from the shaft. For key-connected hubs, three-legged or four-legged pullers are generally used for disassembly. The selected puller should match the external dimensions of the hub. The right-angle hooks of the puller's feet must be properly combined with the rear side of the hub, which will not cause slippage when forced. This method is only used for the disassembly of a wheel with small interference. For a wheel with large interference, the heating method is often used, or a hydraulic jack is used for disassembly at the same time.

Cleaning, cleaning and quality evaluation of all parts of the coupling is an extremely important task after the coupling is disassembled. The assessment of parts and components refers to the comparison of the current status of the size, shape and material properties of each part with the quality standards determined by the design of the parts after operation, and to determine which parts can continue to be used and which parts should be After repairing, which ones belong to newer parts that should be scrapped.

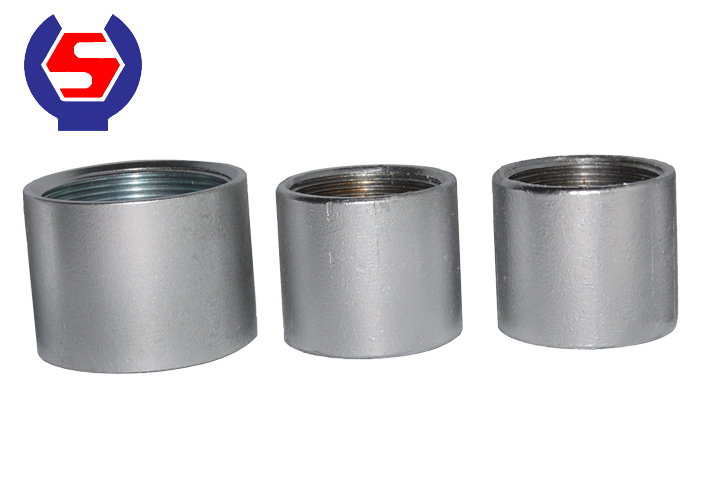

Our company provides BSP threaded pipe nipple.