Elbow can be divided into stainless steel elbow and carbon steel elbow according to different materials. Although the stainless steel material can keep the surface of the stainless steel elbow from being corroded and rusted for a long time. But stainless steel does not need to be cleaned. Some people may think that cleaning up stainless steel is just fine. In fact, this is not the case. There are also some points to pay attention to when cleaning up stainless steel. Today, the pipe fittings manufacturers will talk to you about the main points of cleaning stainless steel elbows.

1. The cleaning of stainless steel elbow needs to be cleaned by alkali cleaning, water-soluble cleaning agent, chlorine solvent blasting or shot peening according to different surface conditions and workpiece requirements.

2. Generally, for the cleaning of stainless steel elbow, the pickling method is used. Correct cleaning can effectively improve the safety performance of stainless steel elbow and prolong its service life.

When welding the elbow, the electrode should be kept dry. This can prevent the surface of the electrode from being contaminated with oil or other dirt, which can increase the carbon content of the weld or affect the quality of the weldment. Not only that,

When the elbow is welded, if it is repeatedly heated, it will precipitate carbides, reduce corrosion resistance and mechanical properties, and have high hardenability after welding, and easily crack.

Therefore, if the same type of electrode is used for welding, pre-heating above 300 ° C and slow cooling around 700 ° C after welding is required. This is an important step related to welding quality and must not be skipped. If the weldment cannot be subjected to post-weld heat treatment, a chromium-nickel stainless steel electrode is required.

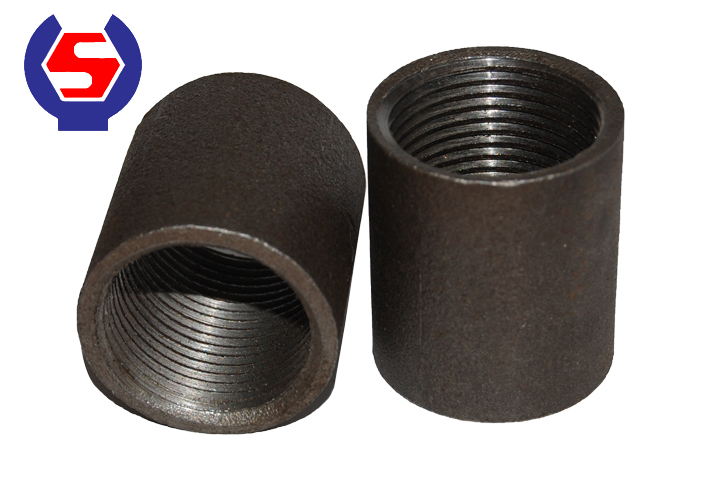

Our company provides Carbon Steel Coupling.