Installation techniques for cast iron drain pipes

The installation skill of cast iron drain pipe has the following aspects shared by Carbon Steel Pipe Fittings Manufacturer.

1. The cast iron drainage pipe trench backfill shall be laminated and compacted. If the pipe crosses the road, in order to avoid crushing the pipe body, coarse sand can be backfilled to the pipe top.

2. If the pressure is tested with water unconditionally, air can also be used.

3. For the convenience of installation, soak the rubber ring with water first.

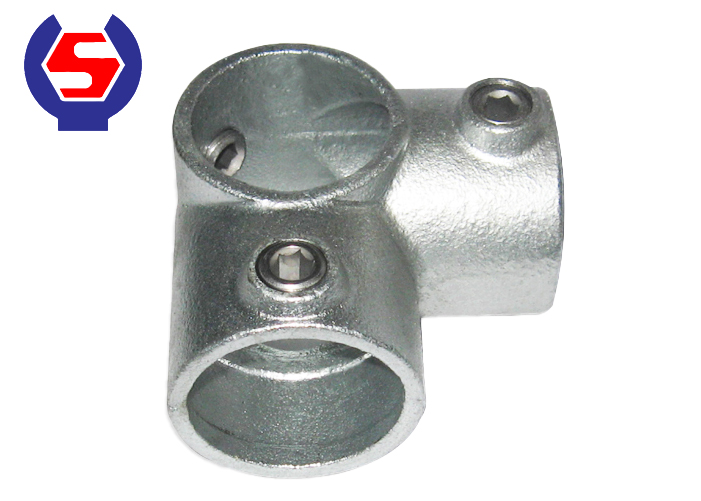

4. Tee and elbow must be made into concrete piers.

5. During the construction process in summer, the interface can be appropriately covered with soil.

6. In the construction, sometimes dripping occurs at the interface of cast iron drainage pipes. In order to avoid this phenomenon, the construction shall be carried out in strict accordance with the specifications during installation. It is necessary to ensure that each cast iron pipe fitting is installed in place. For large-diameter pipes, it is necessary to check the situation of each interface apron.

7. In hot summer, vegetable oil is suitable for lubricating oil; In cold winter, the rubber ring can be preheated by hot water to reduce hardness and quickly installed.

8. If it is necessary to borrow rotation during the installation of the pipe, if the borrowing Angle of the pipe cannot be satisfied, the pipe socket can be cut and bevel according to the required borrowing Angle after calculation, which can not only increase the borrowing Angle, but also ensure the safe use

Sanyu cast pipe products with strong technical force and advanced production equipment, and through strict management, so that the enterprise has a rapid development, product quality level. The company with high quality products, reasonable prices, a full range of services to win the industry and the majority of users.

That's all for the sharing,and we supply 45°Bends Malleable Iron Pipe Fittings, if you have any demand for our products,just feel free to contact us.