Maintenance skill of ductile iron pipe

It can be said that the maintenance of ductile iron pipe should start from its selection. Before the project starts, we should conduct a visual inspection of the parts needed, such as pipe parts, rubber rings, elbows, etc., to avoid the use of diseased parts.

The second maintenance focus is the acceptance work time we should pay attention to the impact of long-term stable operation of socket socket under the apron tube (tube), and strive to do in these aspects of the socket without sundries. The rubber ring has been hit by the north rubber hammer not warped, evenly stuck in the groove.

In the maintenance process of ductile iron pipe, because the axis line of moving pipe is deeply buried in the ground, it is necessary to be careful when there is an inclination Angle. If the resistance is too large, do not force excavation to prevent the distortion of rubber ring.

Maintenance of spindles in winter also requires attention to preheat with hot water to reduce hardness and install quickly. In addition, if the ductile iron pipes used in the project absolutely meet the national standard in quality, we should pay attention to the ac-dc dual use of apron, welding, etc.

Shijiazhuang Sunny Trading Co., Ltd. is a professional supplier of pipeline industry. We are also an export agent for some malleable iron factory and carbon steel factory. And a Malleable Iron Pipe Fittings Supplier. With over 20 years of experience and advanced production facilities, we can meet multiple requirements of clients.

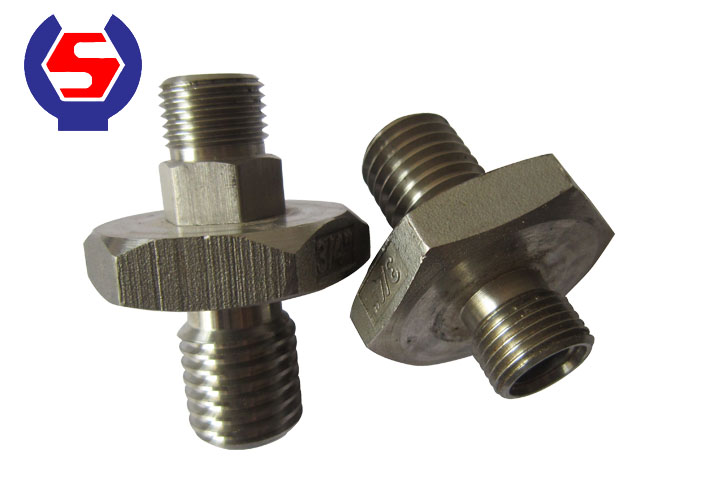

Our main products: malleable iron pipe fittings, steel pipe nipples, steel sockets, beam clamps, tube clamp fittings, hose clamps, air hose coupling & double bolt hose clamps, electrical conduit fittings, castings and other machinery products according to the customers' drawings and samples.