How to fix the pipe when installing ductile iron pipe fitting?

Malleable Iron Pipe Fittings Supplier shares that nodular cast iron pipe installation, how to do pipe ductile cast iron is the most representative of ductile iron pipes, today let's talk about ductile iron pipes using makes some device requirements: before construction, the pipe material, pipe fittings, rubber ring and an exterior view, in order to ensure to be able to normal use. Detailed installation procedures, socket outlets and collation and aprons to the aprons, the tube (tube) to brush on the socket appearance and aprons lubricant, pusher tube to make it into socket and look at it. Detailed device key:

(1) tidy the pipe mouth: remove and wipe all the sundries inside the mouth.

(2) finish the apron ring, on the apron ring: clean the adhesive material on the apron ring, the apron bend into "plum" or "8" shape into the socket groove, and with your hand along the entire apron press once, or use a rubber hammer to smash, ensure that the apron all some evenly stuck in the groove.

(3) in the socket outer appearance and apron coated lubricant: the lubricant evenly coated brush in the socket device good apron outer appearance, in the socket outer appearance coated lubricant will be outside the socket line all parts of the socket brush evenly.

(4) under the pipe: should be under the demand of the pipe to the bottom of the groove, usually can use the manual under the pipe method or mechanical under the pipe method.

(5) equipment and equipment: the equipment and equipment will be prepared in place, pay attention not to the arrangement of the pipe parts again pollution.

Push the pipe into the socket: in the device, in order to put the socket into the socket is more labor-intensive, smooth. First, put the socket into the socket and press the socket onto the apron ring in the socket, connect the wire rope and chain, and tighten the chain; 2mm gap should be left between the socket and the socket until the socket is inserted into the socket, and make sure that the space between the outer edge of the socket and the apron is the same.

In the process of the device, the fixed pipe and moving pipe axis should be in a straight line, or simply push out the rubber ring, affecting the quality and speed of the device. Pipe fittings should be flat, straight lines should be formed between pipes, and care should be taken in case of inclination angles. Align the joint of the connecting pipe to the socket. If the resistance is too large, the rubber ring will be distorted. Rubber ring lubricating oil should be used with vegetable oil; Cold winter, the rubber ring can be preheated with hot water to reduce stiffness and agility of the device. Other, if you choose the ductile iron pipe is fit the specification, it depends on the apron, whether the hardness level does not reach the specification, or the apron itself does not fit the specification.

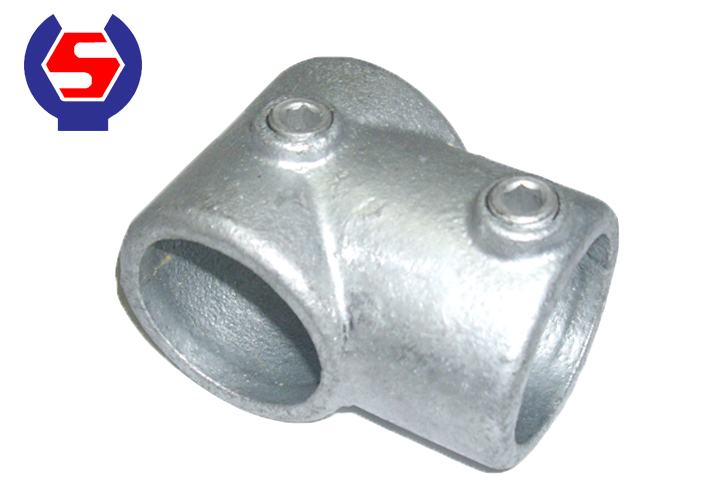

That's all for the sharing, thanks for your reading, and we also supply Malleable Iron Pipe Fittings for sale, if you have any demand for our products, just feel free to contact us.