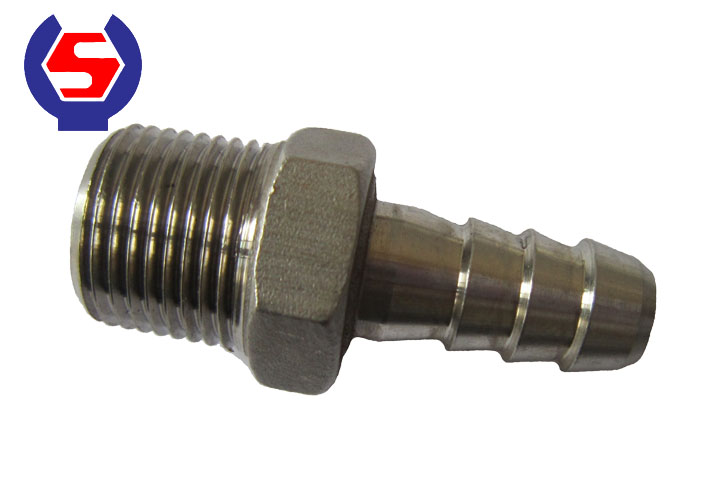

Carbon Steel Pipe Nipples Manufacturer shares with you.

According to the size of the transmitted load, the speed of the shaft, the installation accuracy of the two components to be connected, etc., refer to the characteristics of various types of couplings and select a suitable coupling type. The following points can be considered when making specific choices:

1. The magnitude and nature of the torque to be transmitted and the requirements for the buffering and damping function. For example, for high-power heavy-duty transmission, a toothed coupling can be selected; for transmission with severe impact loads or to eliminate torsional vibration of the shafting, a highly elastic coupling such as a tire-type coupling can be selected;

2. The working speed of the coupling and the amount of centrifugal force caused. For high-speed transmission shafts, couplings with high balance accuracy, such as diaphragm couplings, should be selected, and eccentric slider couplings should not be used;

3. The magnitude and direction of the relative displacement of the two axes. When it is difficult to maintain strict and accurate centering of the two shafts after installation and adjustment, or the two shafts will produce a large additional relative displacement during work, a flexible coupling should be selected;

4. Reliability and working environment of the coupling. Couplings that do not require lubrication are usually made of metal components. This is more reliable; the performance of couplings that require lubrication is easily affected by the degree of lubrication and may pollute the environment;

5. Manufacturing, installation, maintenance, and cost of the coupling. On the premise of satisfying the convenience performance, a coupling that is easy to assemble and disassemble, simple to maintain, and low in cost should be selected.

Our company also provides Carbon Steel Pipe Fittings.