Malleable iron pipe fittings Manufacturer shares the basics of double bayonet fittings.

Installation steps:

Step 1: Insert the tube into the fitting, make sure the end of the tube reaches the bottom of the fitting and tighten the ferrule nut with your fingers.

Step 2: Make a mark at the 6 o'clock position of the ferrule nut.

Step 3: Fix the joint body with a wrench and rotate the ferrule nut one turn and one-quarter turn. At this time, the mark is rotated 540 degrees to the 9 o'clock position.

Working principle:

1. Through the mechanical advance of the screw thread, the sleeve nut moves forward to push forward the rear sleeve, while the rear sleeve moves forward to push forward the front sleeve.

2. The tip of the joint body extrudes the front sleeve inward.

3. The front sleeve eliminates the tolerance between its inside diameter and the outside diameter of the pipe.

4. With the advance of the rear sleeve, the front sleeve moves forward and inward, and the rear end is lifted to form a seal with the inclined plane of the joint body.

5. With the larger deformation of the pipe and the increase of the contact surface between the body and the front sleeve, the greater resistance forces the back sleeve to move inward, thus forming second solid support on the pipe.

6. After the bayonet nut is screwed one and a quarter turn, it advances 1/16inch (1.52mm), the joint complete the seal, holding the tube tight.

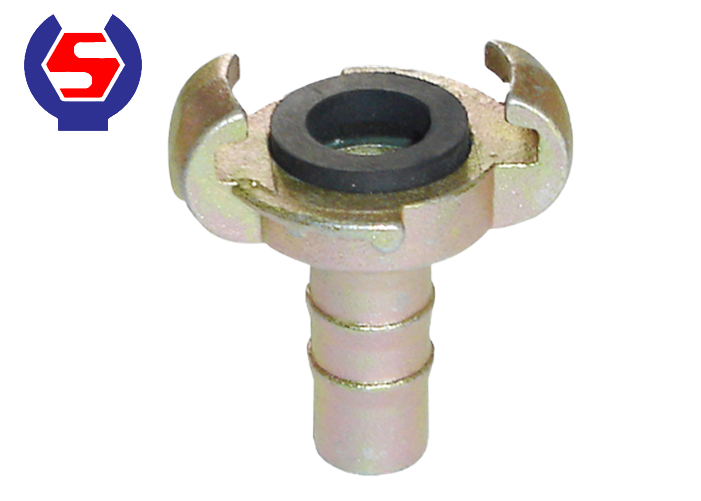

Our company also sells air hose coupling, please feel free to contact us.